Current and Past Projects

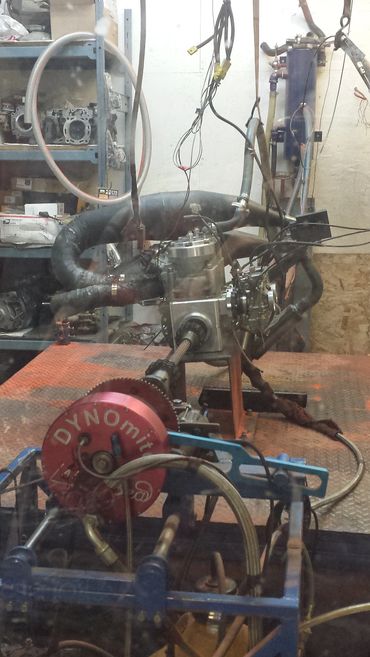

2000cc 2-stroke triple

Robert Cote the CEO of The Mod Shop wanted to build an unspoken and unheard of engine for his dragster back in 2011. Some points that had to be achieved with doing a project like this was it had to be lightweight, compact, and make lots of horsepower. Going with a 2-stroke engine was a great way to make power while being compact and lightweight. Less parts to make and need for the inside of the engine. For the size of engine he wanted, everyone told him he couldn't build one and would not be able to get a crank to make it happen. When you tell Robert that something can't be done, he will go and prove you wrong. He planned out what size, how many cylinders he wanted. what type of fuel system he was going to use, also if this was a carbureted or fuel injected project. What kind of ignition system he was going to use, etc. He then custom machined a crank for the engine and pressed all the pieces together. Once the crank was built, we teamed up with Ralph at Split Second Performance to help with machining with their CNC Milling maching, Ralph got machining the crank cases and head out of a block of aluminum. We went with some blank casted cylinders since it was cheaper and the work for the bore size and Nicasil plating was already done. When we received the cylinders we ported to the specs we wanted to see out of them. We found Wiseco pistons that were already made to the bore size needed so we didn't need to custom make any pistons. The heads were then machined out of another block of aluminum to the compression ratio and squish clearance wanted. For the correct center spacing of each cylinder the arctic cat 900 carbs worked perfect, and it also allowed us to keep it de-tuned. The carbs were gone through and jets were changed for an approximate start. The flywheel housing was machined to use the 800 ski-doo mach z ignition system since it was made for a triple cylinder 2-stroke and incorporated electronic reverse. We also worked with Jaws Performance on this project to design a one of a kind custom pipes for the engine. Once assembled, it was thrown on The Mod Shop dyno and properly tuned. Jaws also had certain specs to properly tune the exhaust system. With everything working properly it put out 330hp and 222ft-lbs torque on 91 octane gas. There is a-lot of performance left in the engine but we kept it de-tuned so we could get everything figured out with the car and clutching. This primary clutch was used on a land speed record snowmobile. No other clutch out there could hold up to the abuse that big horsepower engines could put out. We knew this was a must for this project since its got unlimited amount of adjustments and it can handle the rpm power and torque of the engine. We have added a 100hp shot of nitrous on each cylinder when burning av-gas once we had clutching close.

Turbo Renegade 1000

We are building a custom turbo renegade for our good customer Bill Ford. This project is using the factory maverick turbo engine with the factory turbo at the moment. Possible turbo and cam upgrade in the future after its all running. At the moment we have the turbo mounted and exhaust system built, working on the intake system.

Polaris 850 Sportsman

We are working on some new products for the Polaris 850 atv's. We have the powerhouse full exhaust, and slip on made, that gave great results. Working on another 10+hp with a bolt on part. Stay tuned.

1300cc 2-Stroke Twin Project

We helped out with a 1300cc twin project that Craig Sparks was working on. He bought a blown up Polaris 800 Pro chassis and removed the engine and stuffed this 1300cc twin inside. He had a fun time stuffing the massive twin pipes underneath the hood but he got it done. We helped out with the project by dynoing the engine to get it tuned and helped with some pointers along the way when he had questions.

Copyright © 2020 The Mod Shop - All Rights Reserved.